Fas-Tech

Avenue du Blues N°9

L-4368 Belvaux

Grand Duchy of Luxemburg

L-4368 Belvaux

Grand Duchy of Luxemburg

- + 352 691 592 667

- + 352 691 592 667

- info@fas-technology.com

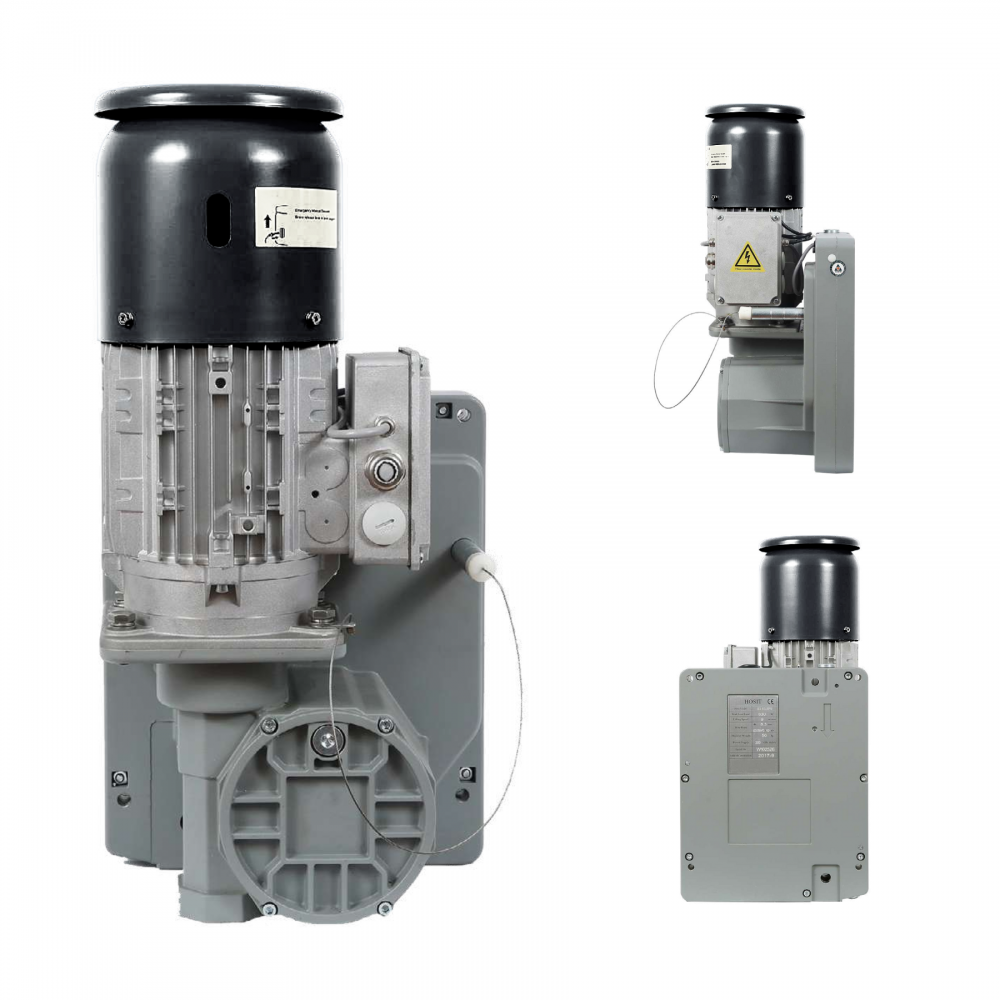

The UNILIFT is a wire rope traction hoist, ROBUST, SAFE and RELIABLE, designed for lifting and lowering people and material at unlimited lifting height.

He is designed and manufactured according to EN1808:2015 and certified by the independent notified body SGS.

With a capacities range going from 500kg up to 2000kg and lifting speeds going from 9m/min to 18 m/min it offers an unparallel versatility in access and lifting applications.

Our hoist has been used in the construction and industry, on elevator installation, suspended platforms, windmill applications and material lifting.

According to the norm, EN1808:2015 hoisting systems in suspended platforms need to comply with a set of different features. When operating at heights safety it’s our primary concern. Because of this, the UNILIFT hoist is designed with in-body safety systems for operation and fall-protection such as:

In addition to the safety the UNILIFT hoist as:

The UNILIFT hoist can be proposed with pendant control, or supplied in a complete platform set ready to use.

Download: DIGITAL CATALOG FAS-TECH

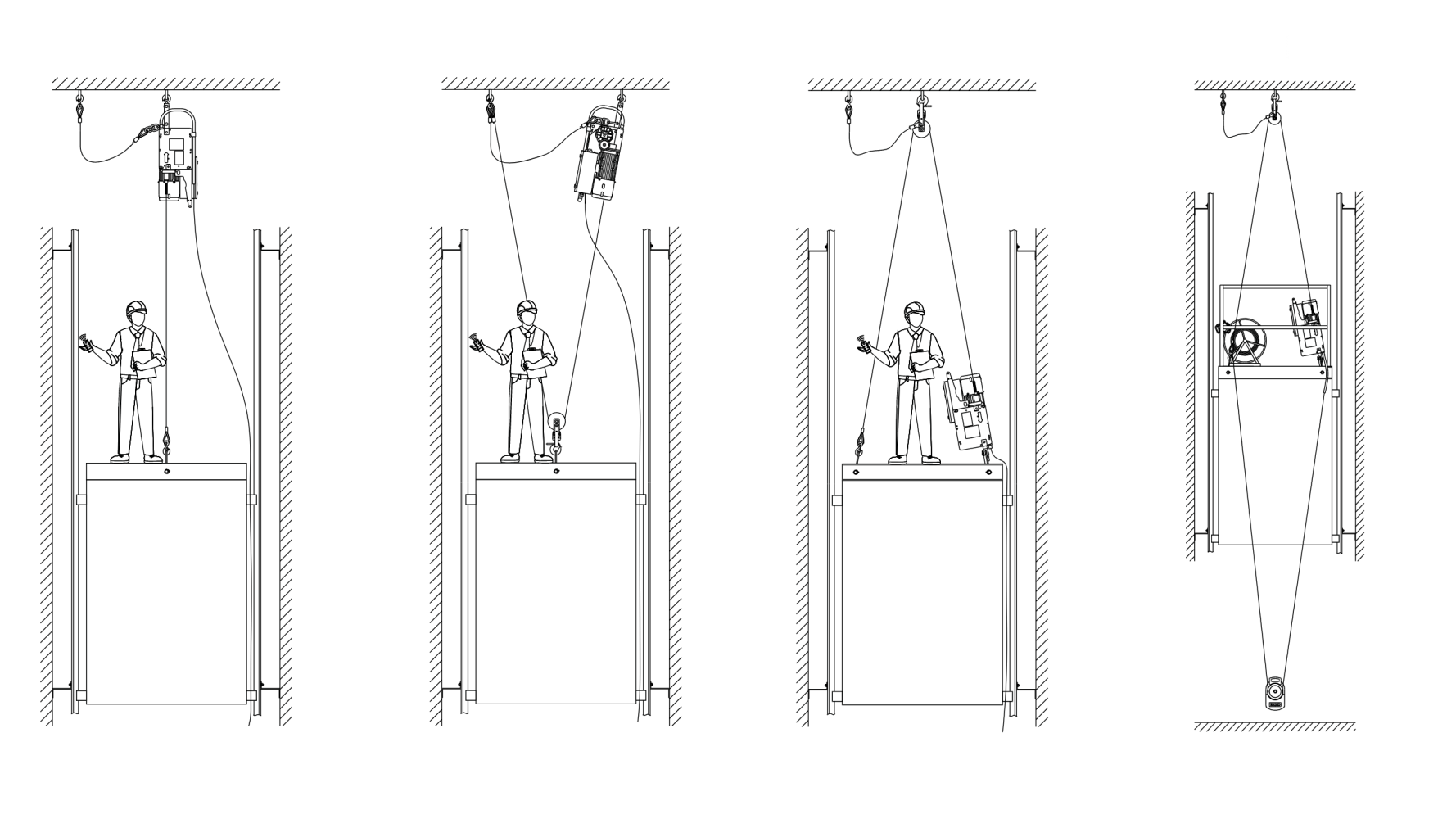

The UNILIFT it's designed for a multitude of man-riding and material-lifting applications.

Elevator installation methods that focus on safety and efficiency use a wire rope traction hoist, to lift their platform or cabin to install all the different elements of the elevator cage.

The UNILIFT hoist equipped with a set of accessories can be adapted to any elevator installation process and help elevator companies to work SMARTER, FASTER, and SAFER at a smaller COST.

Our team of engineers will work alongside you to design the installation system which best matches your process and methods of installation.

Accessories for elevators applications hoists:

Finally, the UNILIFT hoist is easy to maintain and we can for free train your personnel to check, repair and test.

Download: DIGITAL CATALOG FAS-TECH

Download: DIGITAL BROCHURE OF ELEVATOR INSTALLATION SOLUTIONS

With “α” cable-guiding system the UNILIFT hoists have a single drive pulley.

The grip of the wire rope on the pulley obtained by a set of rollers, operated by a pressure spring unit.

Each hoist used for passenger complies with the requirements of the Machine Directive and the EN1808.

All the required safety devices and securities have been integrated as a standard.

Benefits of scaffold-less methods of elevator installation:

Check out all the components you can find in one of our kits:

1 - Traction hoist with integrated control box

2 - Lanyard with shock absorber

3 - Roller tension weight

4 - Pendant control

5 - Extension for pendant control

6 - Shackle

7 - Adapters

8 - Wire rope

9 - 5-core Industrial Socket (HTCN)

10 - Metal box

11- Ropewinder

12 - Adapter ( hook )

In accordance with the requirements of the EN1808:2015, each hoist used for manriding, must be combined with a safety system on the secondary safety wire rope.

A safety fall arrester is a separate mechanical unit that can automatically lock the safety wire rope when the working (Loaded) wire rope is broken or the suspended platform tilts to its limits and/or falls quickly.

The specific safety lock is chosen according to the working conditions of the platform and the working load of the hoist.

According to the triggering mode of the safety locks, they are divided into two categories: